Environmental Product Declaration (EPD)

The Emerald Eco-Label EPD Program will release the next tool for creating EPDs for the national asphalt industry beginning in April, 2022.

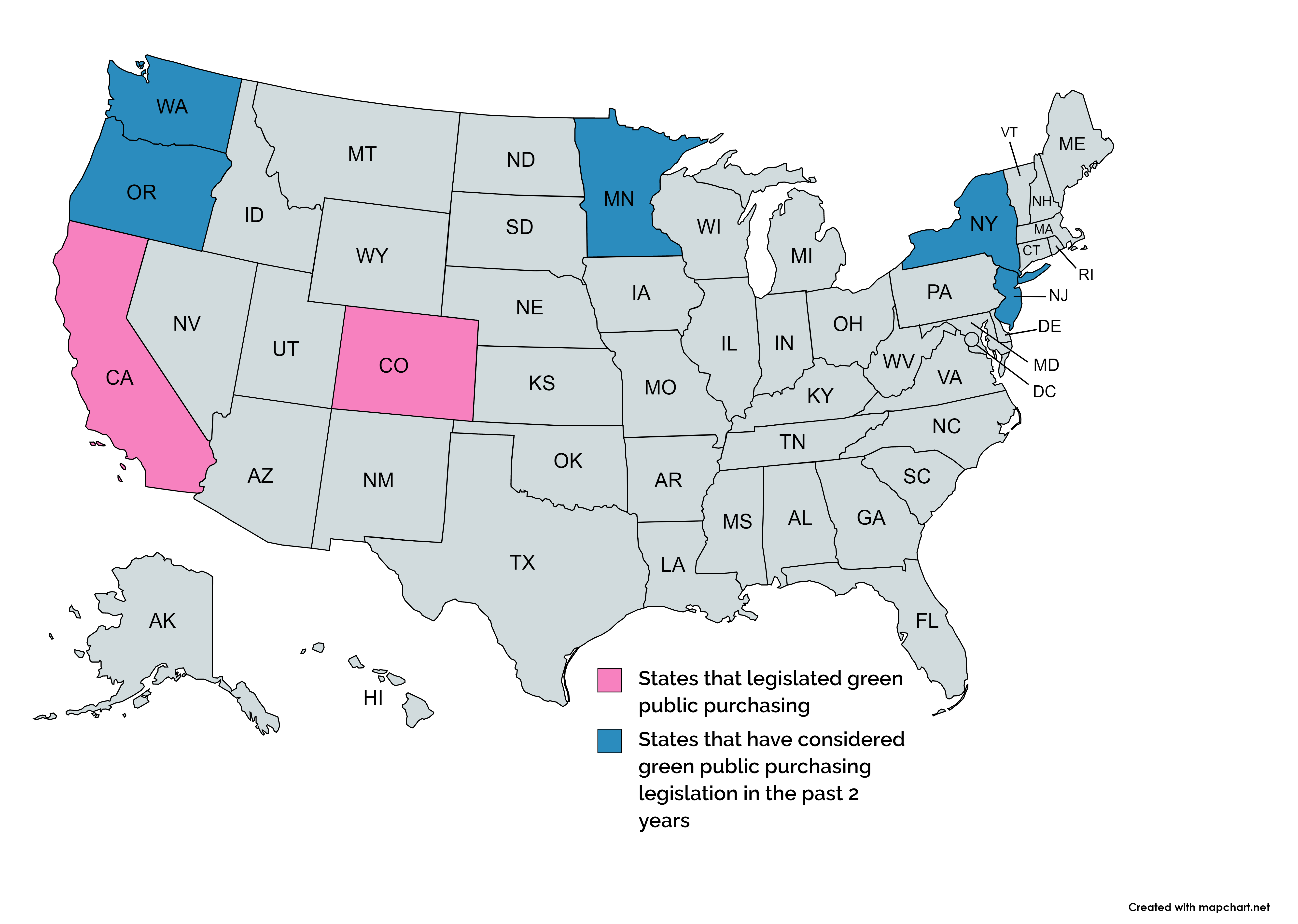

Environmental Product Declarations are labels that publicly quantify and disclose ONLY the environmental aspects of a product, in this case, asphalt mix. Sourcing, manufacturing, use, transportation, and disposal of your product are all considered in an EPD. Currently, some jurisdictions are adopting policies requiring a certain degree of clean products to be made. There are potential federal policies that may require EPDs to be used in the near future.

A Product Category Rule (PCR) has been developed by the NAPA PCR committee to determine what information should be disclosed to the public, and how the environmental impacts are considered. It defines data requirements, life cycle stages to be considered, calculation methodologies, “Functional Unit”, and reporting criteria. Don’t get too stuck on this because NAPA takes care of all of this for us.

An EPD is the document customers want. Because they follow a PCR, EPDs created under this tool are specific to the asphalt industry alone. EPDs for asphalt production cannot be easily compared to the concrete or plastics industry. This tool allows us to look at the environmental impact of 1 ton of asphalt mix per mix design at a specific asphalt plant. We will be able to evaluate whether some mix designs are more impactful towards the environment than others.

Inventory Analysis

- Primary Data (Production Facility Resource Usage)

- Secondary Data (Material Supplier Resource Usage)

- Functional Unit

Data inputs needed (Per 2017-2022 EPD Toolkit)

- Production Facility Resource Usage

- Annual Production and Electricity

- Total asphalt mix sold per year (must be same 12-month period as other plants)

- Water usage (asphalt production and dust control water only)

- Electricity (total electricity use for the 12-month period)

- Onsite Generator

- Fuel type and total units of fuel over 12-month period

- Burner

- Fuel type and total units of fuel over 12-month period

- Oil Heater

- Fuel type and total units of fuel over 12-month period

- Equipment (e.g. loaders)

- Fuel type and total units of fuel over 12-month period

- Material Suppliers (Binder, Agg., Binder Addit., Mix Addit.

- Binder Additives are any additives added to your binder at YOUR production facility

- If mixed at terminal, include binder addit. In the binder section.

- Mix additives are put directly in the mix, e.g., fly ash, fibers, etc.

- RAP and RAS added later

- Needed information (Binders)

- Source Name

- Contact personnel information

- Ingredient

- Description

- Additive/modifier

- Percent of binder by mass

- Needed information (Aggregates)

- Source Name

- Contact personnel information

- Ingredient

- Description

- Needed information (Binder Additives)

- Source Name

- Contact personnel information

- Ingredient

- Ingredient Category

- Description

- Needed information (Mix Additives)

- Source Name

- Contact personnel information

- Ingredient

- Ingredient Category

- Description

- Defining an Asphalt Mix Design

- ***Tool assumes that you track the materials at your production facility as a % of the total mass of the mix.

- Specify mix ID

- Temperatures (Min & Max)

- RAP content if any

- RAP binder percent

- RAS content if any

- Baghouse fines content

- Select Agg.

- Percent ton of mix

- Transportation of agg to facility (distance and method)

- Repeat for additional agg. In use

- Select Binder

- Percent ton per mix

- Transportation of binder to facility (distance and method)

- Repeat for additional binders in use

- Select Binder additives if any

- Percent ton of mix

- Transportation of binder to facility (distance and method)

- Select Mix additives if any

- Percent ton of mix

- Transportation of binder to facility (distance and method)

- CONGRATS, YOU MADE AN EPD

- Binder Additives are any additives added to your binder at YOUR production facility

- Annual Production and Electricity

EPD Results are just numbers!

- Unless you have technical expertise then they do not have much context

- Weighing and Normalization are ways to put number into context

- Typical impact categories

- Climate Change, kg CO2-Equiv

- Stratospheric Ozone Depletion, kg CFC11-Equiv

- Eutrophication, kg N-Equiv

- Smog, kg O3-Equiv

- Acidification, kg SO2-Equiv

- Water Use, Gallons or M3

- Fossil Fuel Depletion, MJ

- Hazardous Waste, kg

The 2022 EPD Toolkit information and manual will most likely be published mid-March. Below is a non-exhaustive list of new data collection items added to the tool since the 2017 version.

- The 12-month tonnage of production waste (startup/shut-down waste, baghouse fines, etc.) that is sent off-site for disposal (in a landfill) or recycling (including beneficial reuse), and the distance to the final destination.

- Information from the company’s safety data sheets (SDS), as well as a weblink or email address for where to get a copy of the SDS.

- The distance that RAP is transported from the initial storage or processing location to the plant.

- The distance that RAS is transported from the processing location to the plant.

Advertising for training webinars by NAPA will begin sometime next week (02/14/2022).